5 strategies to help repairers efficiently purchase high-quality laptop keyboards

In the laptop repair industry, timely supply of high-quality keyboards is the key to ensuring service quality and customer satisfaction. As a professional supplier, we are well aware of the challenges faced by repair personnel in the procurement process.

This blog will help you efficiently purchase suitable and reliable laptop keyboards from five major strategies to improve the competitiveness of your repair business.

- Accurately identify market demand

- Strictly control product quality

- Compare suppliers in multiple dimensions

- Optimize procurement costs and inventory

- Establish long-term cooperative relationships

1.Accurately identify market demand

Maintenance personnel need to have a deep understanding of the usage scenarios and demand preferences of customer groups. For example, repair orders for gamers usually require high-performance keyboards with mechanical switches and full-key anti-collision functions; business users prefer quiet, thin and light keyboards with shortcut function keys.

By analyzing past repair records, counting the repair frequency of different types of keyboards, and combining market trends to formulate procurement plans, ensure that the inventory can meet both common repair needs and emerging trends.

You can also use market research tools to understand the local ownership of different brands and models of laptops, focus on purchasing keyboards with large ownership, accurately match market demand, and avoid blind stocking and waste of resources.

2.Strictly control product quality

a. Technology and material evaluation

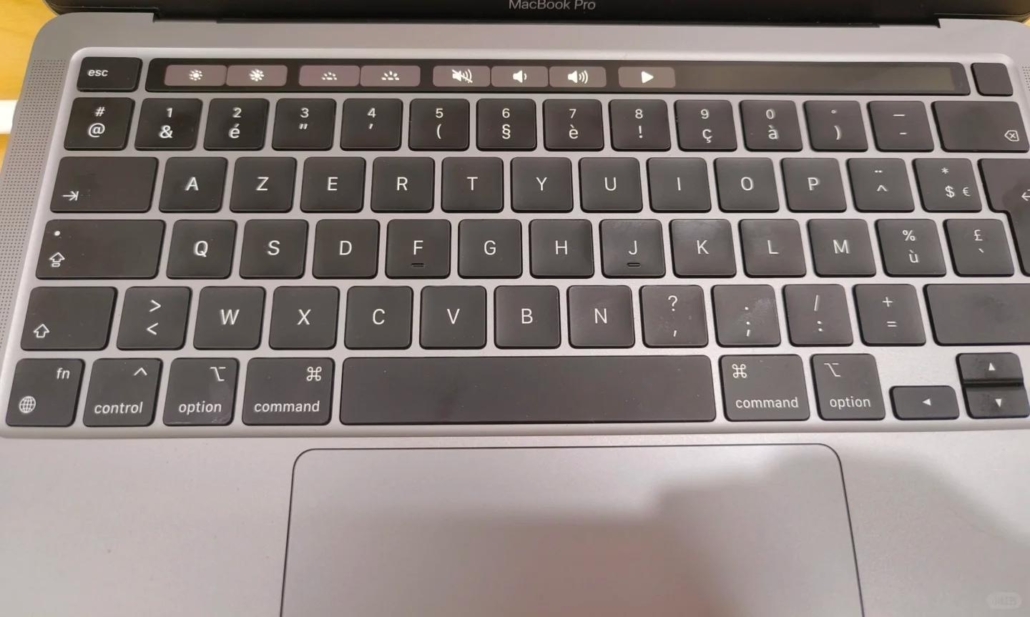

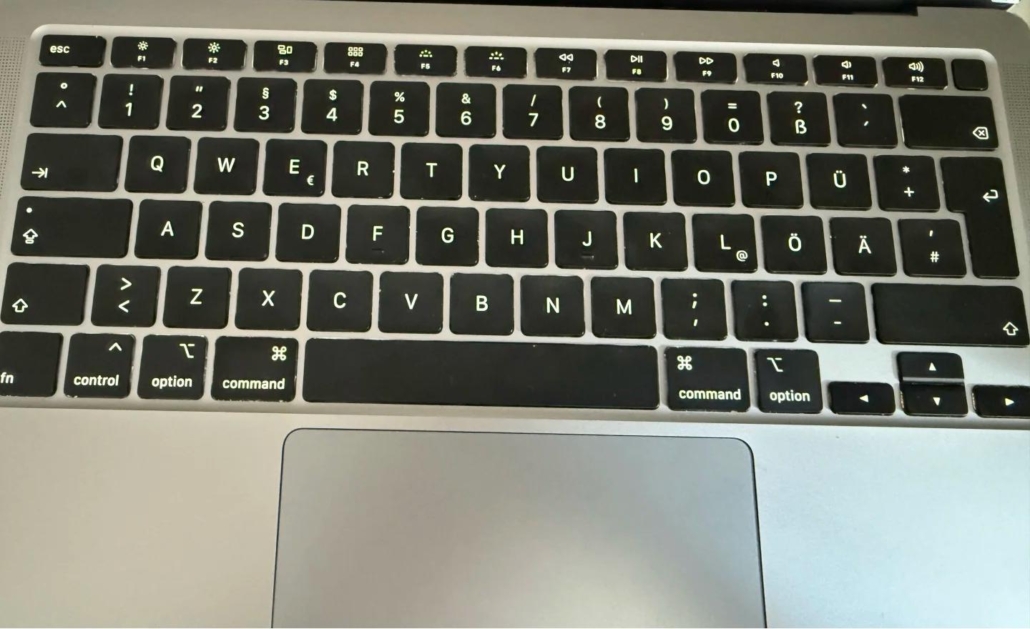

The technical type and material of the keyboard directly affect its performance and durability. Membrane keyboards are low-cost and simple in structure, suitable for price-sensitive customers, but the key life is relatively short; mechanical keyboards have a good feel and long life, but the price is higher. When purchasing, maintenance personnel need to choose the appropriate type according to the positioning of the maintenance equipment.

b. Quality certification and test reports

Give priority to keyboard products that have passed international certification to ensure that the keyboard meets safety, electromagnetic compatibility and environmental protection standards. Ask the supplier for key life test and electrical performance test reports to understand the stability of the keyboard under long-term use and complex environments.

3.Compare suppliers in multiple dimensions

a. Production and service capability inspection

Visit the supplier’s production workshop on site or through video to understand whether its production equipment is advanced and whether the production process is standardized. Suppliers with automated production lines can ensure product consistency and stability.

At the same time, pay attention to the supplier’s after-sales service, such as whether technical support is provided and whether the return and exchange policy is flexible. When encountering keyboard compatibility issues during maintenance, timely technical guidance from suppliers can effectively improve maintenance efficiency.

b. Industry reputation and customer evaluation

Understand the reputation of suppliers in the market through industry forums, social media groups and peer exchanges. Check the evaluation of suppliers’ past customers, focusing on product quality stability, delivery punctuality, communication response speed and other aspects.

Choosing suppliers with a good reputation in the industry can reduce procurement risks and avoid affecting the normal development of maintenance business due to product quality or supply problems.

4.Optimize procurement costs and inventory

a. Bulk procurement and bargaining strategy

Negotiate bulk procurement discounts with suppliers based on the volume of maintenance business. Purchasing a large number of keyboards at one time can obtain more competitive prices.

When bargaining, not only pay attention to the unit price, but also strive for more favorable payment terms. At the same time, compare the quotations of different suppliers, combine product quality and service, and choose the most cost-effective procurement plan.

b. Dynamic inventory management

Use inventory management software to monitor the inventory quantity and in-and-out situation of keyboards in real time. Set a safety inventory warning value. When the inventory is lower than the warning value, replenish it in time to avoid delays in repair orders due to out-of-stock.

Analyze the repair cycle and frequency of keyboards of different models, increase the inventory appropriately for popular models, and reduce the inventory for unpopular models, improve capital turnover, and reduce inventory backlog costs.

5.Establish a long-term cooperative relationship

Establishing a long-term and stable cooperative relationship with high-quality suppliers can bring many advantages. Long-term cooperative suppliers are more willing to provide repairers with priority supply rights to ensure that you can get the product in time when the market is out of stock.

Through in-depth cooperation, you can also participate in the trial and feedback of new products from suppliers, understand new technologies and new products in the industry in advance, and provide customers with more cutting-edge repair solutions.

In addition, long-term cooperation helps both parties to build trust, and it is easier to reach a consensus on price adjustments, product improvements, etc., to achieve mutual benefit and win-win results.

Through the above five strategies, repairers can more efficiently purchase high-quality laptop keyboards and improve the quality of repair services and operational efficiency.

As your reliable partner, we will continue to provide high-quality products and professional support to help you develop steadily in the maintenance market.

Leave a Reply

Want to join the discussion?Feel free to contribute!